Ever heard the phrase, “Time is Money?” In the dietary supplement industry, like any other industry, products need to be shipped to the customer to complete the sale. And, since shipping the product is generally dependent on quality control approving the test results for release, time is of the essence.

Being organized and having a plan will help keep things moving quickly. One idea for improving the quality control process is to review all incoming raw materials and determine what testing can be completed before the blending process. Heavy metals, residual solvents, pesticides, identification, potency or assay, microbiology and other testing can be completed on the raw material. For example; heavy metal levels should not be affected by the manufacturing process, so screening the raw materials should provide accurate results when the product is released. This can be a huge time saver in the long-run.

If so much testing can be done at the beginning of the process, then what are we waiting on? Often, microbiology testing is the last step to complete before the product can be shipped. And since microbiological contamination is common in the manufacturing process, microbiology screening needs to be completed on the raw materials and again on the finished product before it is shipped. Technology and science have come a long way and this has given us rapid micro test methods, which can be completed within 48 hours. Although these tests are not appropriate for every product matrix, they can be used with many products. This rapid testing saves time and can potentially save money.

Potency and label claim testing are also required for finished products. These tests are often complicated in the supplement matrix. Since USP/FCC methods are usually designed for the raw material matrix, once these ingredients are blended together, interferences may be found where recovery may be difficult. Testing is the only way to determine what potency markers are possible to measure. Once you know your product, you can tailor the appropriate finished product testing for the final release specifications.

Getting organized; testing your raw materials; and having a plan for finished product release testing, will go a long way in shipping your products faster. Additionally, using an ISO 17025 accredited testing lab that is proficient in the methods you require will also reduce the delays. And in those rare instances when everything seems to go wrong, SORA Labs can RUSH the testing you need to get you out of a bind!

Taking the Mystery out of Enzyme Blends

Enzyme blends are complicated to understand, but appropriate testing can help solve the mystery that is often associated with these. There are several recommended tests for enzyme products that are identified by Good Manufacturing Practices (GMPs). These include: identity, potency, contamination and/or adulteration

It is possible to identify enzymes in a blend with mini-assays for many of the common enzymes on the market. These ID tests are not FTIR fingerprint tests, but instead show that the enzyme is still working and has not been deactivated by heat or humidity. If the enzyme in the blend does not have this wet chemistry identity test available, then the full potency assay could be completed with the ID listed as “positive per assay.”

For enzyme potency claims, most manufacturers measure enzyme activity units, “by input.” This is applicable because enzymes have interactions that are unique to each blend. When trying to follow GMP’s and FDA regulations, it’s important to test your finished products to meet all label claims. Testing of the blend is possible, but your results may differ from the “input” activities on the label because by definition, enzymes are proteins that act as catalyst for biochemical reactions. Testing the blends is the only way to fully understand these interactions. Some of the common interactions can be read here.

Since contamination can come from several sources, it is recommended to test enzyme products for common culprits such as heavy metal or microbial contamination. Heavy metal contamination could be introduced with tainted water that is used in the fermentation process or with carriers used in the drying process. Microbial contamination may come from improper handling, dirty equipment or other surfaces that have not been cleaned properly that the material touches.

Product adulteration, often the result of supplier mistakes or dishonest practices, may be difficult to identify. Research should be done to determine if there are any known adulterants for that specific material. While it’s impossible to test for every adulterant known for each ingredient, we can certainly test for specific ones that have been found to be an issue in the past. One known adulterant affecting the enzyme market is chloramphenicol. Chloramphenicol is an antibiotic that was used overseas to clean equipment or control microbial growth and consequently became a residue in finished material. With chloramphenicol being a known issue, material screening can effectively identify the presence of chloramphenicol residue. SORA Labs developed an in-house validated chloramphenicol testing method based on the FDA LIB4306. This in-house method specifically detects chloramphenicol in the enzyme matrix using the HPLC MS/MS. A proud accomplishment, SORA was recognized at the NA Residue Conference for outstanding development. More information on chloramphenicol testing can be found here.

Enzyme blends are complex, but choosing the right testing lab will go a long way in demystifying what testing is needed to ensure your products are safe and of the highest quality. SORA Labs has the enzyme expertise with this matrix and many other enzyme activity methods on their ISO 17025:2005 scope of accreditation. Let SORA Labs solve your enzyme testing mystery today!

View our June Newsletter!

Check out our June Newsletter here.

Got botanicals? Read this.

Botanical ingredients, like all raw materials, need a wide range of Botanicals are subject to a host of many different possible contamination issues and testing is needed to determine if these materials are safe for your products. Botanical contamination can stem from many different factors such as the soil in which they are grown; how they’re kept free of insects and microbes; and processing they’ve undergone. Determining the proper identity of the botanical and active marker content is also proven through As part of your overall quality strategy, here is a few testing recommendations for your botanical ingredients.

- Identification: The importance of identity testing has been a hot topic of conversation this year. Through the testing process, it is important to use compendial methods and reference standards when available. Identity testing is a GMP requirement and ensures that the correct raw material is being used in your product.

- Heavy Metal Testing: Heavy metals (As, Cd, Hg, Pb) could be present in the soil that the botanicals were grown. Plants can absorb these metals and ultimately contain high levels of these harmful metals.

- Microbiological: Botanicals can have a high risk of micro contamination. Location and farming procedures along with the handling procedures in harvesting and packaging can all contribute to micro issues. Testing all incoming lots will give you the information needed to ensure a quality, finished product can be manufactured.

- Pesticide Testing: Many farmers utilize pesticides to protect their crops from damage caused by insects and other bugs. Even if a product is labeled “pesticide free” or “organic” you still need to verify the accuracy of the label. Harmful chemicals could run off in waterways or be carried from one farm to the next. These chemicals cannot be seen by the naked eye, and can only be detected by testing the material for pesticide residues.

- Residual solvent testing: Residual solvent testing becomes extremely important if solvents are used to make botanical extracts. Testing will ensure that your ingredient is free of these chemical residues.

- PPSL (Pulsed Photo Stimulated Luminescence): This analysis is used to detect ingredient irradiation. Irradiation practices are used to keep the micro counts low. Irradiated materials must carry special labeling to alert the customer.

- Other testing: Botanical marker or other testing will be needed to check the potency of the botanical ingredient. Other specific testing may also be needed to find adulterants known to be a common contaminant for that ingredient.

When using botanicals in products, it’s imperative to include the appropriate testing before the product goes to market. SORA Labs performs all testing mentioned above and we’re great at finding what may be lurking in your botanicals. If you have any questions about the testing of your ingredients, feel free to contact us.

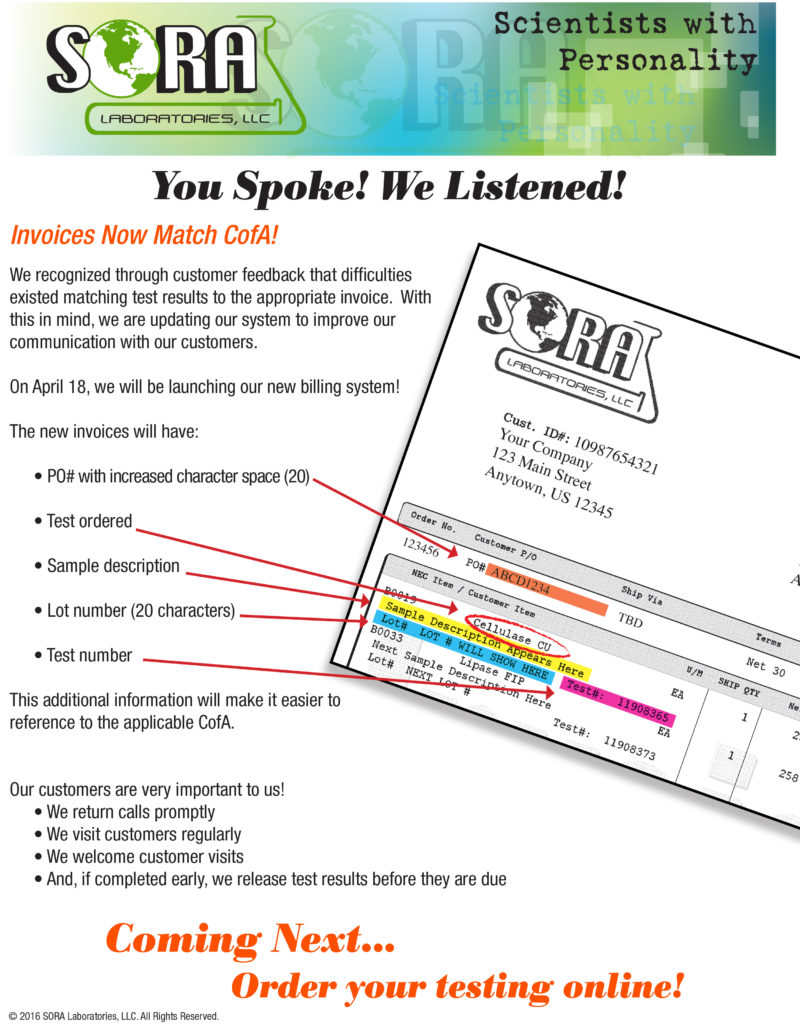

You Spoke! We Listened!

Arsenic, Cadmium, Lead, and Mercury…Why Should You Care?

Heavy metals—What are they and why should you be concerned about them? The elements known as heavy metals include arsenic, cadmium, lead and mercury. These elements can be present in the soil that your materials are grown in or found in facilities where your products are produced. These contaminates can pose a health risk to your consumers and could even cause poisoning if they are consumed in high enough quantities. Due to their high health risk, the FDA requires testing for these analytes to be compliant with their GMP regulations. You may be asking yourself some questions regarding this testing and SORA Labs is here to answer them! Some of the most commonly asked questions and their responses are below:

Q: What stage of manufacturing can you test for heavy metals?

- Raw Material

- When you test your raw materials, you are more likely to catch a “bad” ingredient before you add it to your blend and ruin your entire batch.

- Finished Products:

- Finished product testing confirms that the product meets required standards once all ingredients are blended and no heavy metal contamination occurred during the manufacturing process.

Q: Why Choose the ICP-MS method?

- There are other methods that can be utilized for heavy metals analysis, however, ICP-MS allows the laboratory to achieve lower detection limits when compared to ICP-OES. This lowered detection limit allows for more accurate and precise data on your product.

- Prop 65 requires certain limits of heavy metals to be met. Some prop 65 results can be obtained by ICP-OES; however, the serving size becomes a large factor. By using ICP-MS the factor of serving sizes becomes less of a deterrent. We are now able to achieve prop 65 levels on a larger variety of serving sizes.

If you have any remaining questions, please do not hesitate to contact us. SORA Labs would love to assist you with making sure your consumers are getting a top quality product! We offer ICP-MS heavy metal and mineral testing along with many other assays, ID and contaminate testing needed in the dietary supplement industry. Contact us today!

Probiotic and Enzyme Testing-As featured on Natural Products Insider

Check out our most recent article on Natural Products Insider!

Testing for good bugs?

Over the last couple of months our focus has been on the bad “bugs” that could be present in your supplements. However, not all bugs are bad! Probiotics are the good “bugs” that could be your consumer’s best friend. Probiotics occur naturally in our body, but certain factors such as antibiotics, stress, poor diet, and even aging can diminish their presence and our body. When this decrease occurs our bodies need a bit of a boost to keep a healthy balance. You may find yourself asking why these little organisms living in mainly our intestines are so important to our bodies. This is because they enhance the intestines’ barrier function, compete with and suppress pathogenic bacteria, and modulates and stimulates immune system activity.1 So, when your consumers turn to your product to help provide the much needed probiotic boost are they receiving the product they think they are?

When you begin the discussion of probiotic testing, it can be a very worrisome topic; however, SORA Labs is here to help you out! Many probiotic testing methods are very vendor specific. This means that where and who you purchase your probiotic raw materials from is a major deciding factor as to how they are tested. Due to the many strains and their unique characteristics, there is not a single method that will provide an accurate, true representation of the enumeration of multiple strains in a finished product. Once they are blended together, you can try testing each strain by the method most suitable for it; however, some overlap may occur providing inaccurate numbers. Therefore, SORA Labs recommends the testing of single strain raw ingredients to ensure that you are putting what you think you are into your products. SORA Labs has the capabilities of performing many of the vendor methods and we are always expanding our testing capabilities. If you have a probiotic product that needs to be tested, please feel free to contact us!

Reference:

1: Fedorak RN, Madsen KL. Probiotics and the management of inflammatory bowel disease. Inflamm Bowel Dis. 2004 May;10(3):286-99. VIA http://www.lifeextension.com/magazine/2009/1/optimize-digestive-health/page-01

2: http://www.webmd.com/digestive-disorders/features/what-are-probiotics

Are you testing your raw ingredients?

In recent years, the FDA and other governing bodies have been tightening regulations for dietary supplement companies. Seen in the recent attacks by the NY attorney general and other agencies, they have criticized companies for mislabeling ingredients. It was unfortunate for the companies on the receiving end of these attacks because the agencies used non-traditional testing methods, which have not been proven to be effective at identifying the purity of raw ingredients. As a result, these companies faced loss of consumer trust in their products and it undoubtedly affected their bottom line. So how can you protect your company from events like this? Testing your raw ingredients is the best way to address this concern!

According to 21 CFR 111.120, companies are required to determine whether all components, packaging, and labels conform to specifications that are established in 21 CFR 111.70 (b) and (d). These specifications are provided for each component (raw ingredient) that is used and must be established as follows:

(b)

- You must establish an identity specification.

- You must establish component specifications that are necessary to ensure that specifications for the purity, strength and composition of the dietary supplements manufactured using the components are met.

- You must establish limits on those types of contamination that may adulterate or may lead to adulteration of the finished batch of the dietary supplement to ensure the quality of the dietary supplement.

(d)

You must establish specifications for dietary supplement labels (label specifications) and for packaging that may come in contact with dietary supplements (packaging specifications). Packaging that may come into contact with dietary supplements must be safe and suitable for its intended use and must not be reactive or absorptive or otherwise affect the safety or quality of the dietary supplement.

If you pay close attention to (b) you can see how the testing of your raw ingredients is mandatory. The minimum requirement is for ID, purity and strength to ensure your raw ingredients are what you are claiming. This documentation is also very important when you test your finished product and notice matrix interference occurring after testing has been completed. Matrix interference can cause certain analytes to be much higher or much lower than your anticipated label claim. When you have documentation of the quality of your raw ingredients, it allows for a written documentation detailing the unexpected results for reference if your product is ever under scrutiny.

What went wrong?

In the wake of the CBC retraction of the November 2015 dietary supplement report due to testing inaccuracy, questions are being asked about the function and processes of third party laboratory With so many different labs offering testing, how is one to know if the accepted practices are being followed? What makes a lab trustworthy in their methods? What could have happened that caused the tests to go wrong?

What is required of a lab to receive their accreditation? There are many factors that go into receiving an ISO 17025 accreditation. These are just a few examples of some practices that must be followed for a lab to be accredited:

For a lab to be ISO 17025 accredited, they are required to do proficiency testing, which means testing the same sample by multiple analysts, preferably between different labs and comparing the RSD% (Relative Standard Deviation) of the results. There are tight ranges for these results that show proficiency.

ISO 17025 accreditation is specific to certain lab tests and not all tests that a lab runs are within their ISO 17025 scope of accreditation. The ISO 17025 certificate for each lab lists the accredited tests. This accreditation is considered to be the lab’s expertise.

The Preventive/Corrective Action system (PCAR or CAPA) is used for any lab issue to improve all company practices. ISO 17025 accreditation requires continual improvement, so when a lab error is found, a PCAR is then generated to solve the problem for future

Out of Specification (OOS) results require a lab investigation as part of the ISO 17025 guidelines and Good Lab Practices (GLP). Each lab is responsible for accuracy, so when results are out-of-spec, the lab will double-check many things including: sample handling practices; reagent expiration dates; if equipment calibration is up-to-date; dilution factors; and testing calculations. In addition, the lab should verify that the method was followed as written and if it was valid for the sample matrix. Along with other considerations, it is important to ask if the sample appeared to go fully into the solution? If a lab error is found, retesting and retraining should be conducted. Since this investigation takes additional time, samples that are OOS will be delayed due to this process.

What steps should a lab take to make sure that their results are accurate? What are some suggestions for avoiding mistakes?

SORA double-checks the results of each testing run against a known “known or reference standard.” For enzyme activity assays, this standard is just an extra sample of “known value” included the run to ensure that it is being performed according to procedural guidelines. This result is recorded and the RSD% is calculated. The result must fall within a range set by the validating method for the entire run. If the known or reference standard falls outside of the given range, the run is considered invalid and all results are thrown out—invalid results are not reported to the customer.

Labs should follow the practice of validating the method on a new sample matrix. This can be a long expensive process, with testing often expected on a fast turn-around time, so this process is rarely done. A quick check for method performance can be done on the new sample matrix using “spike recovery” Spike recoverytesting involves adding a known amount of the chemical you are looking for in the sample matrix and then seeing what your method recovers on the matrix. The results can help you decide if the method will work on the new sample matrix.

Issues can also occur during testing if the wrong method was used to run the sample. There may be several potential methods of testing for the same compound so it is always a best practice to ensure that the correct testing method is being used before beginning.

As Stuart Phillips, a scientist at McMaster University who studies the effects of protein supplements on humans, says: “Like anything else in life, I think when a lab gets something wrong, [it can happen for a number of reasons like] human error, contaminated dirty glassware, [or] machine malfunction.” Though things could potentially go wrong, taking the proper precautions and following the accredited procedures will help keep mistakes to a minimum and help ensure correct testing results.